Having a grass trimmer at home is essential for maintaining a gorgeous lawn. It helps ease trim back weeds, tall grasses, and unnecessary foliage. Likewise, STIHL FS94R cares for lawn areas you can’t reach with a lawn mower.

This professional, gasoline-powered shaft trimmer delivers the best power-to-weight ratios in its class. Specifically, the STIHL FS94R combines reliable performance with variable speed control.

Despite being a highly effective landscaping tool, it sometimes encounters problems that make the simple task challenging. We will point out some STIHL FS94R problems and mention their solutions.

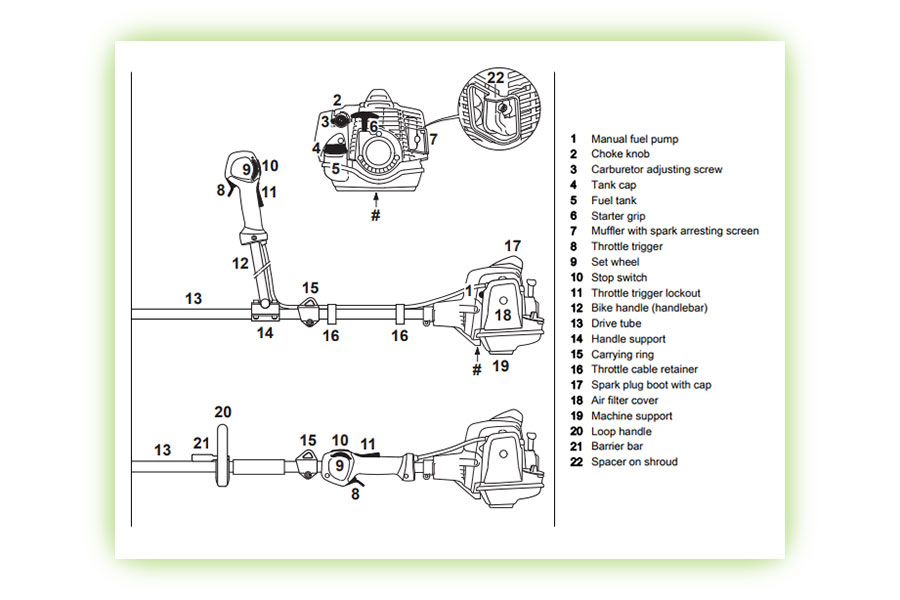

Stihl FS94R Parts

Before we discuss the problems with the STIHL FS94R weed Wacker, it is essential to know the parts of the STIHL FS94R.

STIHL FS94R Problems and Its Solutions

Does your STIHL trimmer stop despite following the correct procedures for using it? Then, the problem may be with the engine, fuel, spark, or air circulation in the combustion chamber. No matter what, there is a way to fix all these problems.

Let’s look into the STIHL FS94R trimmer problems and their solution.

Problem 1: Engine Doesn’t Fire

When you try to start the STIHL trimmer, the engine usually doesn’t start and leaves a gasoline smell. You possibly followed the proper guideline to start the STIHL trimmer but failed.

Possible Reasons – The STIHL FS94R carburettor may be flooded.

How to Fix It?

Wait for 10 minutes before you try to start up your STIHL trimmer again. Follow the steps below to start the STIHL FS94R.

Problem 2: A Sputtering Engine

The engine sputters but won’t entirely start. It’s a sign of a lean fuel mixture in the combustion chamber. That means the engine is down on power, making it difficult to run at idle speed.

Possible Reasons – The air filter or spark arrestor may be clogged.

How to Fix It?

Locate the air filter behind a plastic cover on the side of the engine housing. And the screen attached to the muffler by a single screw is the spark arrestor. Follow the steps below to fix the clogged air filter or spark arrestor.

Problem 3: Spark Plug Problems

The engine may be down on power because of spark plug problems. The spark plug is usually rated for 100 hours of use. If the spark plug needs to be repaired, it either won’t spark or weakly.

Possible Reasons – Possibly, it’s time for spark plug replacement. Or, a dirty air filter causes deposits to build up in the engine, which leads to fouled spark plug.

How to Fix It?

Problem 4: STIHL Trimmer Head Problems

The STIHL FS94R trimmer starts and runs, but the trimmer head doesn’t spin as it should. This is a common problem with trimmer heads.

Possible Reasons – Clogged trimmer head, clogged air filter or spark arrestor, lack of lubrication, and improper placement in the gearbox.

How to Fix It?

The first thing to do is to look over the equipment and check its overall condition. Then, check around the trimmer head to see if any fibrous plants and roots are twisted tightly. If any, you may have to cut them with a knife.

Problem 5: Arcing

Arcing mainly happens if the adapter nut is missing or loosened. It could ignite combustible fumes. Working with a loose or missing nut in an explosive or easily combustible temperature can lead to an explosion. It can cause damage to property or severe injury.

Possible Reasons – Loosen or missing adapter nut.

How to Fix It?

Problem 6: Loss of Engine Power

Along with making weird noises, there can be a noticeable loss of engine power at times.

Possible Reasons – Clogged air filter

How to Fix It?

You need to clean or replace the air filter. Follow the step below to clean the air filter.

Problem 7: Fuel Problems

STIHL FS94R mostly requires an equal amount of oil or gas mixture to run. If you fail to add oil and gas mixture in the specified ratio, the engine can seize. Also, the trimmer shouldn’t be kept idle for an extended period with a full gas tank. It can cause fuel to clog the carburetor.

Possible Reasons – Improper ratio of oil and gas. Clogged STIHL FS94R carburetor.

How to Fix It?

You need to drain or clean the carburetor. However, it may be a strenuous job. Check the gas cap, if it is adequately tightened. If not, the fuel delivery system won’t work correctly. After solving the carburettor issue, take the STIHL FS94R to a technician.

Problem 8: Unnecessary High Loads

A trimmer run at high revs for the first three tank fillings can cause unnecessary high loads. The full-throttle offload happens during the break-in period.

Possible Reasons – When the trimmer runs at high revs during the break-in period.

How to Fix It?

A factory-new machine must not run at high, especially during the break-in period, to avoid unnecessary high loads. The frictional resistances in the engine may be greater during the break-in period.

Read also: 9 Common CFMOTO UFORCE 1000 Problems & Fixes

Final Thoughts

Now that you have learned how to fix the STIHL FS94R problems. Although STIHL recommends doing all the repairs and maintenance by STIHL dealers, it’s cost-efficient to do it yourself. So, find out the problems and fix them NOW!